SERVICES

SUN HYDRAULICS MACHINES

Optimized & Industry-ready Solutions

For All Your Complicated Needs

We are highly professionals in manufacturing Hydraulic Machines, We offer the best service & solutions to various industries,

“Service is what life is all about”

SUN HYDRAULICS MACHINES MANUFACTURING PROCESS

COMPRESSION RUBBER MOULDING PRESSES

- Single daylight 3&4 Plate ejection system as per requied, with precision Grinded

Platens. - Electrically Heated Platens with Digital PID Temperature Controllers.

- Single or Battery of Presses operated with common hyd. Power pack, Suitable for

automatic Push Button oparation with or without safety curtons.

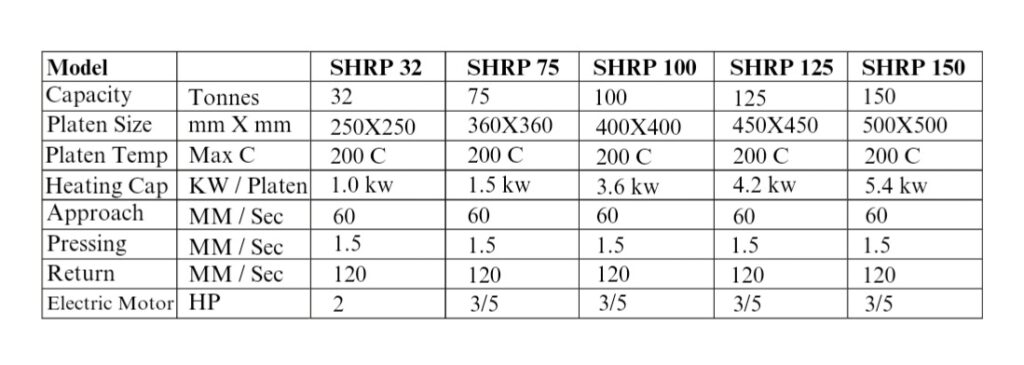

SPECIFICATIONS

Recently we are coming up with

1. Vacuum Moulding Press & Injection Moulding Presses

2. Rubber Bale Cutting machine.

COMPRESSION / TRANSFER RUBBER MOULDING PRESSES

- Four / Three plate automatic Moulding opening facility.

- Automatic component ejection from the Mould inside to regualte heat loss.

- Selection of cycles as per requirement.

- Suitable for components with metal inserts, Bellows and horizontally split Moulds

with automatic ejection facility.

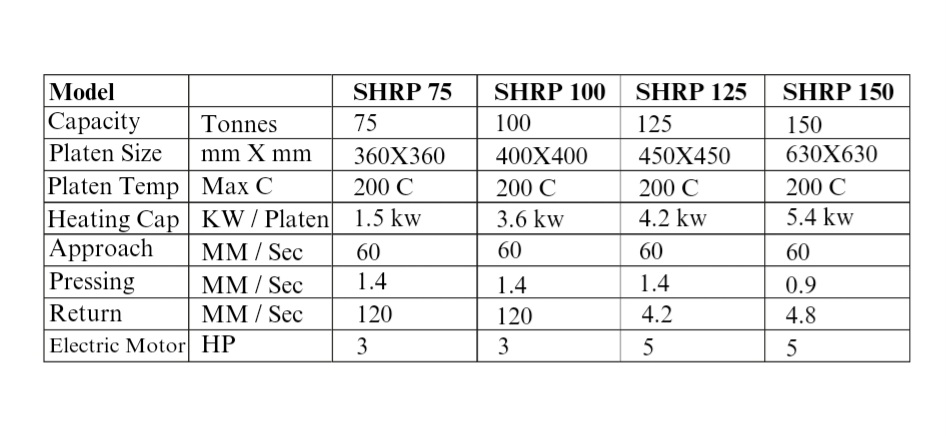

SPECIFICATIONS

Our Innovations

Industry Focused Machines

RUBBER MOULDING HYDRAULIC PRESSES

A rubber molding hydraulic press is a machine used for shaping rubber compounds into desired forms using heat and pressure. It consists of a hydraulic system that applies force to a mold, which contains the rubber compound.

A heated mould tool and the pressure of a clamping press are used to form the rubber. The curing or vulcanisation process takes place before the final portion is removed and cooled. An open mould with an elastomer blank positioned in the cavity is used in compression moulding.

USES OF RUBBER MOULDING HYDRAULIC PRESSES

Rubber Hydraulics Press can be used to make O ring, sealing parts, oil seal, auto parts, rubber crash pad, rubber air spring, key board, medical rubber parts, rubber bottle stopper, silicone wrist band, water-stop tape, bridge support/bridge bearings, rubber cable, electronics insulators etc

HYDRAULIC EQUIPMENTS

Hydraulic machines are widely used for their ability to transfer a substantial amount of power through flexible hoses and small tubes. Hydraulic systems can move heavier loads and provide greater force than pneumatic, electrical, and mechanical systems.

Hydraulic tools operate using the force created by pressurized fluids. The force is transferred as energy through the system to initiate the machine’s dynamic components to complete a wide range of tasks and applications.

HYDRAULIC VALVES

These valves regulate the direction of hydraulic fluid within the system, directing it to different devices as needed. They can control the direction, acceleration, or speed of actuators

Spools are central to the operation of directional control valves, as they are responsible for directing the flow of hydraulic fluid. By moving within the valve body, the spool redirects fluid to different paths, facilitating various functions like stopping the flow, allowing flow, or changing its direction

SPM HYDRAULICS PRESSES

SPM Hydraulics presses is used to maintain the static pressure and configure various types of metals, plastics, rubber, and wood. The hydraulic press machine plays a significant role in the fabrication, assembly, and production of components for machinery and parts for commercial and industrial products.

Within the hydraulic press, there is a piston that works as a pump,that provides a required mechanical force to a particular area of the sample. There is another pistol in it that has a larger area and produces a larger mechanical force.

HYDRAULIC PUMPS

A hydraulic pump converts mechanical energy into fluid power. It’s used in hydraulic systems to perform work, such as lifting heavy loads in excavators or jacks to being used in hydraulic splitters.

Hydraulic pumps convert electrical energy into fluid pressure by using an electric motor to drive the pump. They are necessary for all hydraulic drives. The fluid pressure is then delivered by hydraulic fluid to cylinders and actuators and hydraulic motors at the required pressure level and volume.

HYDRAULIC ACCESSORIES

AUTO MOBILE SECTOR

Throughout the history of automotive development hydraulics have played a critical role in the engineering of brakes, steering and gears, as well as suspension.

MEDICAL SECTOR

That simplicity is obvious in the common syringe, a device used at clinics and hospitals worldwide. Applying force to the plunger enables the syringe to withdraw or expel liquids

FOOD GRAD SECTOR

A specialized rubber gasket ensures no food or beverage is contaminated during any process condition. These gaskets are fabricated from materials that maintain the highest levels of sterility