SUN HYDRAULICS

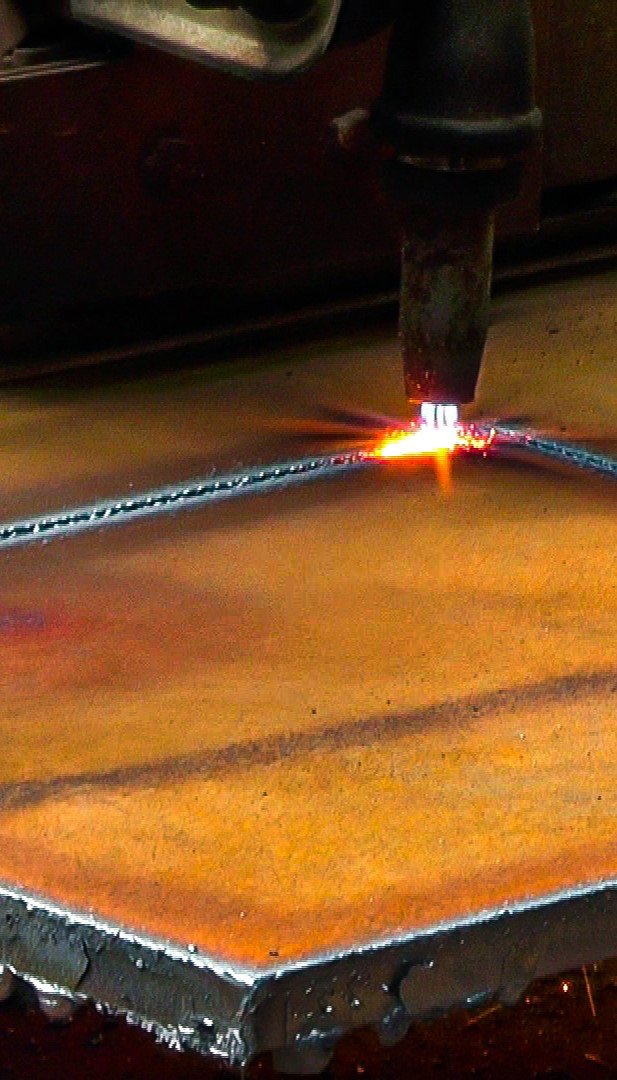

Sun Hydraulics is one of the Leading Manufacturers of Hydraulic Rubber Moulding Presses, Specially in Custom Built Design, 25 Years of Excellence Experience With Quality At It's Best!

WINNER of INDIA 5000 Best MSME Award 2017

COMPANY PROFILE

SUN HYDRAULICS has been established in 2000 for Repair and Maintenance of Hydraulic Equipment’s, Since 2003 the Unit has been specializing in manufacturing of Hydraulic

presses based on the principles of “Best quality”, “Total customer satisfac-

tion”, “Continuous improvement” and “Persistent Management”. Our presses

are designed to adapt various vulcanization technology in rubber related

products and especially for Auto Mobile Components, transportation equip-

ment’s, electronic parts, sporting goods, and for Indian Defence equipment’s and

many more related Industries

Vijayanand Roadlines Ltd. (VRL) – The first customer for maintenance of Hydraulics Equipment’s & Kirlosker Electric Company (KEC) Hubli for maintenance, We have supplied Hydraulics Cylinders to the KEC and other subsidiary Mechanical Products for maintenances then switched to conversion of Mechanical RUBBER MOULDING presses to Hydraulics presses for Pune.

Why Choose Us ?

KEY POINTS TO SELECT SUN HYDRAULICS MAKE HYDRAULIC RUBBER MOULDING PRESSES

SUN HYDRAULICS MANUFACTURING :

- SUN HYDRAULICS is Manufacturing four Pillar types Design Press with ground & hardchome plated pillars, giving precise pressing

movement of plates, which enables to use secured moulds in the presses, hence no need to take moulds out of the press every time,

ensuring minimum heat loss. Moulds are opened by press itself, so as to increase mould-life and accuracy, resulting in to minimum flash.

SUN HYDRAULICS RUBBER MOULDING PRESSES :

- SUN HYDRAULICS Rubber Moulding Presses are controlled by International branded programmable logic controller. Being solid state

circuitry,it is more reliable and gives trouble free service with choice to decide any sequence of operation

SUN HYDRAULICS RUBBER :

- SUN HYDRAULICS RUBBER Moulding Presses, number of breathings, breathing duration, curing time, etc. are Programmed through HMI to

PLC. Hence alteration in the Cycle is not possible by unauthorized person, which ensures quality of products, particularly in the night

shifts.

HYDRAULIC SYSTEM :

- Hydraulic System is designed with latest features All solenoid valves are operated with like -230 VAC supply which improves solenoid life

and working easily available after: sales During curing period, electric

motor stops but when pressure drops below certain value, auto-

-matically starts and maintains the pressure, causing less strain to hydraulic system. Thus less electricity consumption, less noisepollu

-tion, less wear and tear of pumping unit, but it provides constant curing pressure. Vertical pumping unit, manifold mounted cartridge

valves. Continuous filtering of oil.

HYDRAULIC MAIN CYCLINDER :

- Hydraulic main Cylinder is single acting and push pull cylinders manufactured from forged steel casting 1S2062 bars precision machined

honed and assembled with latest Polyurethane / Bronze filled Teflon Seals, which gives all the movements of press under precise

command of PLC including breathing or Dealing cycle. In contrast to single acting cylinder design where return is by gravity which mean

moulds opening, De-Gasing etc , not under control.

TOP COMPANIES WE HAVE WORKED WITH

SATISFYING INDIRECT VENDORS AND OUR SUCCESS STORIES

SUN HYDRAULICS MACHINES

Our Innovations

Industry Focused Machines

Rubber Moulding Hydraulic Presses, SPM Hydraulic Presses, Hydraulic Equipments, Hydraulic Pumps, Hydraulic Valves & Hydraulic Accessories